Electric machines

Electric machines exercises

EM-1. Voltage level and insulation

Investigate influence of the rated voltage level on size and cost of the electric motors by working with the system consisting of a motor and a frequency converter. Take PUMP as the application and design the drive systems for the four sets of pump parameters:

- head 200 m, flow 85 l/s, efficiency 85%, rated speed 2950 rpm;

- head 200 m, flow 145 l/s, efficiency 85%, rated speed 2950 rpm;

- head 200 m, flow 200 l/s, efficiency 85%, rated speed 2950 rpm.

Set motor type to SCIM, cooling to IC411, efficiency class to IE3, protection to IP21. Design the drive system so that machine and converter voltage is around 400 V, then 690 V, then 3300 V and, finally, 6000 V.

- [!] Make sure you keep machine type, efficiency class, cooling, protection class and other parameters except voltage and power the same for all the cases above. Include these parameters in your report.

Record power, weight and cost of motors for the three pumps above and for the four voltages. Present the results as a chart or a table, draw conclusions.

Can you explain the results/conclusions as the electric machines designer, in terms of winding design (insulation, cooling)?

EM-2. Rated speed vs weight, size, inertia

You are chief engineer responsible for powering a new conveyor. You have three helical gearboxes available at the plant's stock: two 1-stage gears with ratios 1:4 and 1:6, and one 2-stage gear (ratio 1:12). Your can buy a motor to match the gearbox or a motor that fits speed of the conveyor without any gearbox.

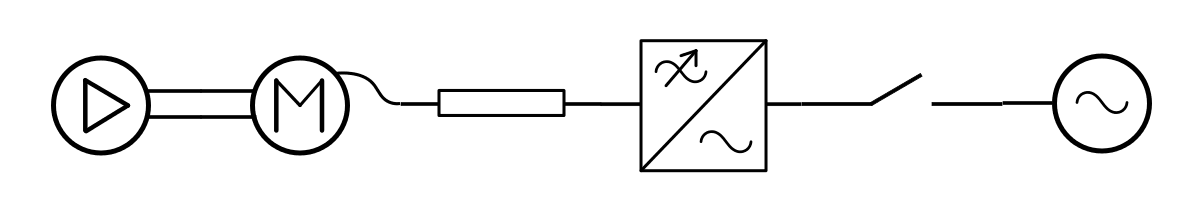

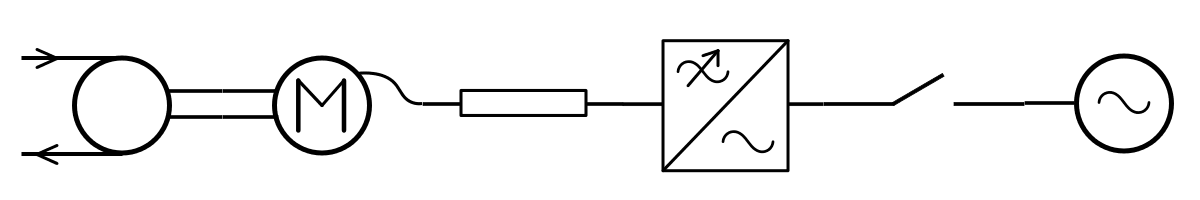

Consider two system architectures; with gearbox and without one (direct drive).

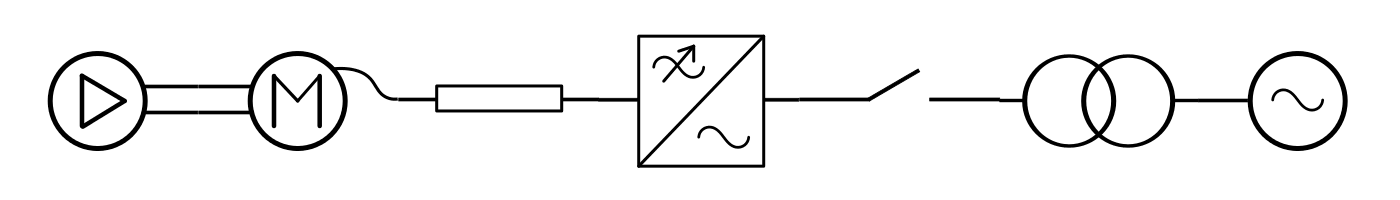

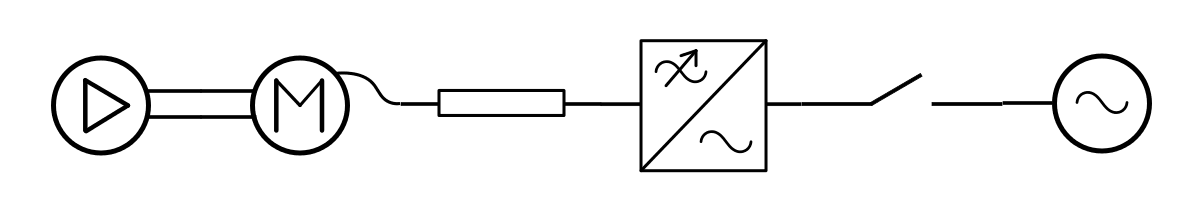

System 1:

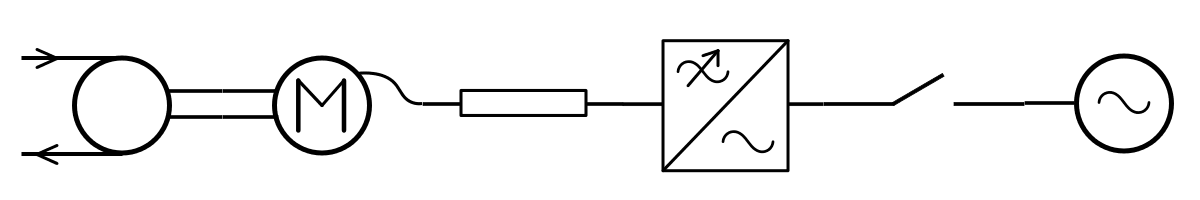

System 2:

For the systems 1 and 2 above investigate influence of the gear ratio on size, cost and inertia of electric motor.

-

Take system 1.

- Set conveyor drum max speed to 230 rpm and min speed to 80 rpm.

- Torque = 9 kNm.

- Take the machine with synchronous speed to 300 rpm @ 50 Hz.

- Record weight, cost and inertia of the chosen motor.

-

Take system 2.

- Set conveyor drum speed to 230 rpm and min speed to 80 rpm.

- Torque = 9 kNm.

- Record speed, weight, cost and inertia of motors for the following gearbox ratios: 4, 6 and 12.

Summarize in results in a table. Explain what you see, draw conclusions. Can you explain the results/conclusions as the electric machine designer?

Use PM machines only!

EM-3. Efficiency class, lifecycle analysis

You are a chief engineer at a plant. Consider replacement of old induction motor (cooling IC411, protection IP21) on a centrifugal pump with either IE3 motor or IE4 motor. The old motor has efficiency corresponding to IE2. Available grid - 400 V. The existing motor is driven by an FC.

Pump parameters: head 50 m, flow 50 l/s, efficiency 82%, speed 1450 rpm.

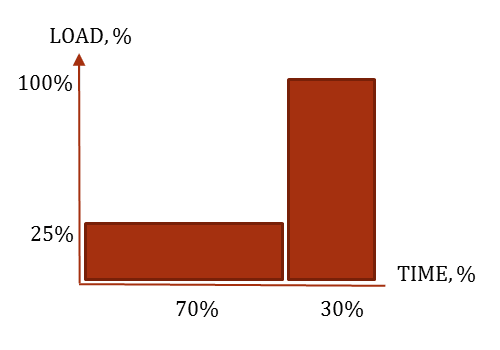

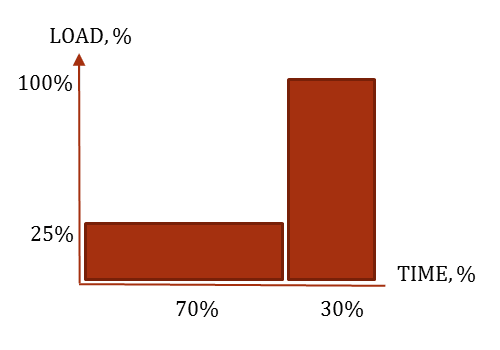

Operational mode of the pump:

- operation at 25% load 70% of time and at rated load - 30% of time

Find LCC (cost of ownership) for all the alternatives

- Energy price - 0,07 Euro/kWh (another variant 0,2 Euro/kWh)

- Operational time - 8000 hours/year

- Service life - 5 years (another variant 10 years)

So, there are all together eight variants to consider:

- IE3 motor, Energy price - 0,07 Euro/kWh, Service life - 5 years

- IE3 motor, Energy price - 0,07 Euro/kWh, Service life - 10 years

- IE3 motor, Energy price - 0,2 Euro/kWh, Service life - 5 years

- IE3 motor, Energy price - 0,2 Euro/kWh, Service life - 10 years

- IE4 motor, Energy price - 0,07 Euro/kWh, Service life - 5 years

- IE4 motor, Energy price - 0,07 Euro/kWh, Service life - 10 years

- IE4 motor, Energy price - 0,2 Euro/kWh, Service life - 5 years

- IE4 motor, Energy price - 0,2 Euro/kWh, Service life - 10 years

What motor (IE3 or IE4) would you choose for each of the four scenarios?

- Energy price - 0,07 Euro/kWh, Service life - 5 years

- Energy price - 0,07 Euro/kWh, Service life - 10 years

- Energy price - 0,2 Euro/kWh, Service life - 5 years

- Energy price - 0,2 Euro/kWh, Service life - 10 years

What general conclusion can you draw on dominating cost components?

EM-4. Comparison of machine technologies

Design drive train for a pump (head 50 m, flow 50 l/s, efficiency 82%, speed 1450 rpm).

Operational mode of the pump:

- operation at 25% load 70% of time and at rated load - 30% of time

Try SCIM (IE2), SyRM, PMSM as the motor type. Calculate Life Cycle Cost (LCC) for each motor variant. Compare the variants on spider diagram. Consider strong and weak sides of the technologies.

- Energy price - 0,2 Euro/kWh

- Operational time - 8000 hours/year

- Service life - 10 years

EM-5. Protection (IP class) vs size and cost

Design drive trains for the four different applications below. Note different environmental conditions where the electric machines will be operating and choose correct IP class for the machines.

Set the same rated speed (300 rpm) and the same voltage (690 V) in all applications. Set PMSM as the motor type.

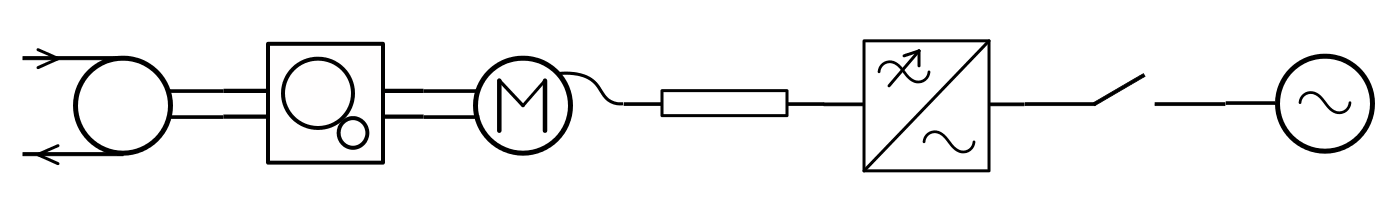

-

Case 1. Pump: dairy (for different trains)

- H=50 m, Q=50 l/s, =79 %, speed 300

-

Case 2. Conveyor: cement plant

- min speed - 100 rpm, max speed - 300 rpm, Torque - 0,9 kNm

-

Case 3. Wind turbine: air conditioned compartment(nacelle)

- Rated speed - 200 rpm, overspeed - 1,2, Torque - 1 kNm

-

Case 4. Winder: Clean paper winding room

- Drum diameter (empty) - 0,3 m, Drum diameter (full) - 0,5 m, Force - 4 kN, Speed of the line (rated) - 3 m/s

Record: mechanism rated power, motor designation, IP class, weight and cost of the electric machines you have chosen for the four applications above. Make sure you keep cooling and other "influential" parameters the same. Include these parameters in your report. Comment on the differences between the motors chosen.

EM-6. Cooling vs size and cost

Imagine you are chief engineer at a paper mill. Design drive train for the winder with given characteristics:

- Drum diameter (empty) - 0,3 m,

- Drum diameter (full) - 0,6 m,

- Force - 16 kN,

- Speed of the line (rated) - 5 m/s,

- 400 V,

- flange&foot mounting of the motor,

- cooling water 30 deg.C is available.

Make sure you keep machine type and efficiency class the same when comparing cooling and protection class variants. Include these parameters in your report.

Solve the problem using power components with (1) air cooling, (2) water cooling. Compare the air-cooled and water-cooled variants. Present the results in the table.

| Cooling | Protection | Weight | OD | Length | Cost | |

|---|---|---|---|---|---|---|

| Case 1 | IC411 | IP54/55 | ||||

| Case 2 | IC416 | IP54/55 | ||||

| Case 3 | IC411 | IP21/23 | ||||

| Case 4 | IC71W |

EM-7. Derating for altitude and temperature

Sales manager of a big electric motor provider have received three very similar requests from Madrid, Mexico and El Alto. In each of the requests they need induction motor to drive a centrifugal pump with head 60 m, flow 50 l/s, efficiency 83% and rated speed of 950 rpm. The motor is to be operated from existing frequency converter which rated voltage of 400 V and power of 45 kVA. Distance between the pump and the FC is 30 m. Other conditions, e.g. cooling, are specified as well. Help the sales manager to make offers for Madrid/Mexico/El Alto. Propose more than one alternative if needed. Include only motors into the offers.

Important details:

- Madrid, Spain - 667 m above sea level

- Mexico, Mexico - 2240 m above sea level

- El Alto, Bolivia - 4150 m above sea level

EM-8. Frame material vs size and cost

Choose frame material suitable for the given environment.

Case 1

Application - food & beverages (wet, acids, etc.)

Take CONVEYOR with drive system with just frequency converter.

Available information:

- One drum to be driven

- No overloads, duty cycle - 100%

- Dusty environment, abundant heat removal capability, wet floor

- Grid 400 V

- Distance between the driven drum of the conveyor and the FC (cable length) - 30 m

- Rated torque 500 Nm

- Speeds: min - 300, max - 400 rpm

Case 2

Application - mining (dusty, mechanical shocks)

Take WINCH with drive system with just frequency converter.

Available information:

- empty drum diameter 0.2 m

- full drum diameter 0.3 m

- linear speed at which the cable is to be reeled on the drum - 1 m/s

- force/tension on the cable 2 kN

- grid voltage 400 V

- no overloads

EM-9. Shaft height and mounting

There is an oil pump with Q=55 l/s, H=50 m, efficiency 82%, speed 1400 rpm. Conditions:

- Clean dry room with abundant heat removal capability.

- Grid 400 V.

- Cable length - 200 m.

The plan is to replace old SCIM driving the pump with IE4 motor. Shaft height of the old motor is 180 mm and the pump is fixed to the frame together with the motor. Is the replacement possible? Consider several variants. Compare them. First consider SCIM only. Then solve the problem using other motor types.

Note that density of oil is not the same as density of water.

EM-10. Thermal capacity & insulation class

Design drive trains for the two identical conveyors with parameters:

- Speed 200...230 rpm

- Rated torque - 9 kNm

One conveyor has duty of 100%, another one - 80%. Grid is 690 V.

Explain the difference in chosen electric machines for the two cases.

Question-1

Could we have used even smaller machine on the second conveyor? If yes, what insulation class should it have had (assume all motors in DriveConstructor have insulation class "B")? If we use smaller machine with the same class "B" as before then what would be insulation lifetime (assume in normal load lifetime of 10000 hours)?

Question-2

Is replacing the motor with insulation class "H" with another motor with insulation class "F" possible? What lifetime should be expected? What if insulation class "H" but temperature rise as for class "F"?